Spray dryer for food industry

-

Spray dryer for food industry. Atomizer. Water evaporation: 200kg/h.

Spray dryer for food industry. Atomizer. Water evaporation: 200kg/h.

Spray dryer for food industry. Nozzles. Water evaporation 800kg/h.

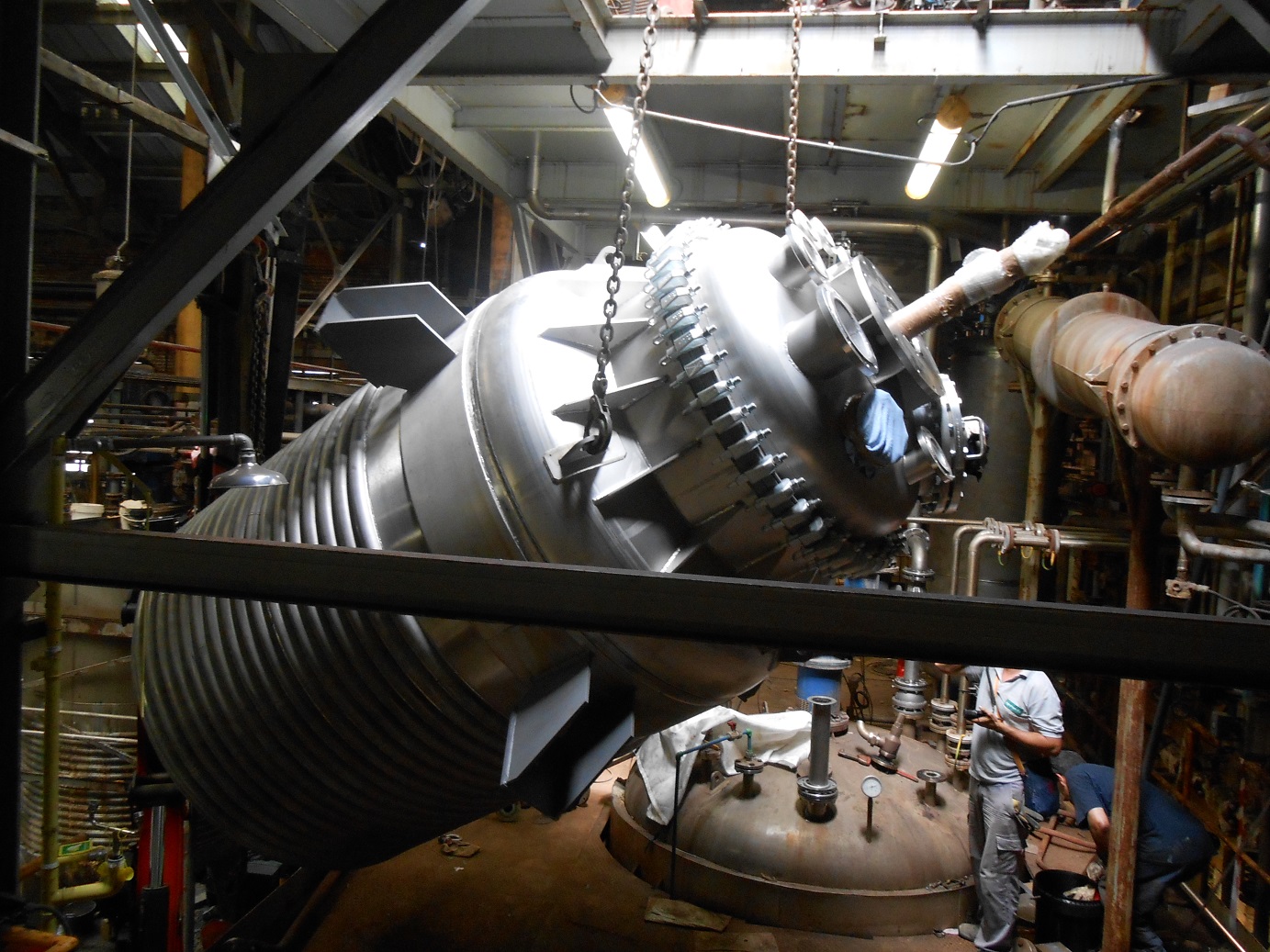

Spray dryer for atomization up to 1.200 kg/h of evaporated water for the chemical sector (1991). Nozzles. Water evaporation 1200 kg/h

Spray dryer for the cemical sector (2007). Nozzles. Water evaporation 1.000 kg/h.

The manufacture of tubular heat exchangers for gas-gas, gas-liquid and liquid-liquid systems in accordance with numerous design codes (AD MERKBLATTER – ASME) with different capacities and exchange surfaces, made to client specifications.

The manufacture, assembly and painting of tubular structures for the housing of precision machinery, automated components, robots, special welding equipment, etc.

The manufacture and assembly of the tubular skid with equipment for wastewater treatment using totally-automated sterilisation procedures.

The installation of an 8-bar steam boiler with a 2,500 kg per hour steam capacity. The manufacture and supply of the support structure and the auxiliary maintenance structure, the construction and installation of the gas train and conduit connection to the existing steam circuit with all interruption devices and necessary instrumentation.

The manufacture and installation of a test plant for sulfonation, reactor manufacture and auxiliary equipment, in addition to the entire support structure, the installation of the structure in modular format (3 units) includes; the location of all major and auxiliary equipment, the connection of all equipment and services by conduits, the installation of pumps, valve fitting and instrumentation for the automation of facilities.

The manufacture, supply and assembly of soundproof booths, consisting of bolted steel tubing with insulated sandwich-construction panels.

The manufacture of atmospheric and pressurised tanks in different volumes, in accordance with different design codes (AD MERKBLATTER – ASME – API650).

Spray dryer for the food industry. Atomizer. Water evaporation 600kg/h.

Change of the production system for whole milk. Atomizer. Water evaporation 600kg/h.

.jpg)

Turnkey status for a new sulphitation plant, equipment and installation.

Turnkey status for the manufacture of a sulphonation facility and sulphone reactor

Manufacture and installation of a DN 3500 treatment plant

Manufacture of a 30 cu. metre reservoir for housing hydraulic fluids.

Manufacture of a black steel tank painted with bituminous paint and stainless steel AISI 304 blocks, with dimensions of 3000 mm in diameter and 11,000 mm in length, and accessories for proper installation.

Adaptation of six air treatment cabins for painting cabins from an automotive plant to an air heating system through a gas burner to replace the current system, based on hot water spools. The adaptation consists of modifying the interior structure, re-situating the first row of filters, pacing a gas burner, making a closure wall with AISI 316 stainless steel sheet metal, placing a gas ramp for gas supply, a protection cell for the burner and a AISI 310 sheet of metal for protection from the flame. Additionally, all adjustments are being carried out to implement appropriate humidity, temperature and air flow parameters.

Installation consisting of modifying an existing boiler room made up of three diesel boilers by adding a new biomass boiler with all auxiliary elements necessary, such as a 25 m3 storage tank, pneumatic transportation to the boiler, connecting it to the existing one, a 10,000 litre holding tank connected to the entire installation, both the hot water and the heating installation. This improves the efficiency of the installation and prevents the diesel boilers from working at the pace they are now.

Making an access control hut in Barcelona, made out of mirror-polished AISI 316 stainless steel, with insulation, electrical installation, bathroom and sanitary installation, as well as a control panel and communications network. Dimensions at 2.5x3x5.2 metres and canopies for the windows.

Modification of the existing installation, consisting of upgrading a reactor to support vacuum and manufacture, supply and installation of auxiliary equipment, 700-litre Florentine, 37m2 condenser and all structures and piping necessary for proper operation. All made with AISI 316 stainless steel, except for the structure which was made with black painted steel.

Manufacture of thermal fluid boilers with different capacities with all expansion tanks associated therewith, all made with carbon steel.

Manufacture, supply and installation of a sodium sulphate silo for the production process at a chemical plant made up of a metallic holding structure, silo, filter, vibrating unloading bottom, weighing hopper, unloading tube, loading tubes, level probes, stairs and access gangways. All made with AISI 304 stainless steel, except for the structure which was made with black carbon painted steel.

Turnkey installation for facilities at a thermal plant to suction carbon dust during their manufacturing process. The installation is composed of a metallic structure to hold the storage silo, a hose filter, and an intermediate hopper to directly unload the collected dust into the lorry. In order to collect the dust, a network of 3 and 5" pipes is installed in the entire plant, with different suction points within the plant, with sleeves and aluminium launching point. Suction is by means of a vacuum, generated through a blowhole pump.

Installation carried out with two differentiated actions:

Manufacture, supply and installation of a CLAV technology sludge dryer, made with AISI 316 stainless steel, with all adjacent elements included, Scrubber, thermal aerators, motors and supply hopper, as well as worm gear screw to supply and empty the dryer, also including electrical installation and remote control of the installation.